author

Richardson RFPD

Energy Storage & Power Conversion

WBG Semiconductors

While silicon is a single chemical substance, silicon carbide is a compound of carbon with silicon. Gallium nitride is a compound of gallium with nitrogen. For this reason, the semiconductors produced using these components are also called “compound semiconductors.”

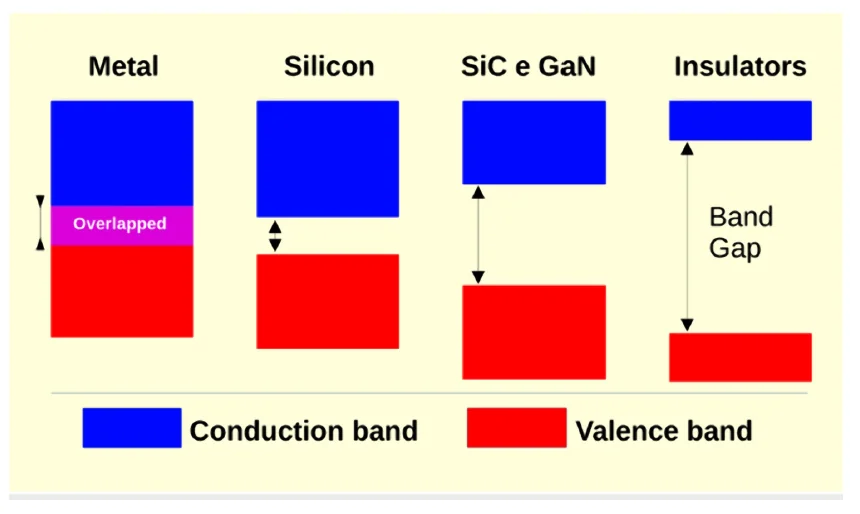

SiC and GaN fall into the category of WBG semiconductors and offer several advantages over traditional silicon semiconductors.

With EVs, renewable energy systems, and next-generation consumer electronics pushing the limits of what’s possible, wide bandgap materials are poised to take center stage.

Advantages of WBG Semiconductors

Silicon has been dominant for many years but is reaching its performance limits in a growing number of existing and emerging applications. SiC and GaN offer important advantages in terms of reliability, energy efficiency, power density, and system size and cost reduction. These advantages give SiC and GaN the potential to enable cutting-edge electronic and optical devices with vastly superior performance compared to silicon.

Because WBG semiconductors can withstand higher electric fields, they can sustain higher voltages. They can also operate at higher switching frequencies, which provides improved performance, minimizes filtering requirements, and allows the use of smaller associated inductor and capacitor components.

When compared to silicon, these factors bring several benefits, including smaller, faster, more efficient, and more reliable operation. Higher voltage capabilities open opportunities in higher power designs with dramatically improved efficiencies, enabling the same performance in smaller form factors—or improved performance in the same form factor. Efficiency is inversely proportional to weight and, ultimately, the carbon emissions associated with the operation of the target application.

Many devices based on WBG technologies also offer the benefit of operating at higher maximum temperatures than their legacy silicon counterparts.

SiC vs GaN: A Comparison

Compared to silicon that has a bandgap of 1.12 eV (electron-volts), GaN and SiC have bandgaps that are around three times higher at 3.4 eV and 3.2 eV, respectively. This means that both can support higher voltages with thinner die; this contributes to higher switching frequency capability. Additionally, there are several material property differences between the technologies that impact how they work and where they are used. The main differences can be summarized as follows:

Electron mobility: The most important difference between GaN and SiC is electron mobility. This is a measure of how quickly electrons can move through the semiconductor material. While silicon has an electron mobility of 1500 cm2/Vs, GaN has an electron mobility of 2000 cm2/Vs, meaning electrons can move over 30% faster than silicon’s electrons. SiC, however, has an electron mobility of 700 cm2/Vs, which means SiC’s electrons are slower-moving than both GaN’s and silicon’s. With such elevated electron mobility, GaN is nearly three times more suitable for high-frequency applications.

Breakdown field strength: GaN and SiC have similar breakdown field strengths—3.3 MV/cm for GaN, and 3.5 MV/cm for SiC. Silicon has a breakdown field strength of 0.3 MV/cm, which means that GaN and SiC are nearly ten times more capable of maintaining higher voltages per unit of die thickness. They are also able to support lower voltages using significantly smaller and thinner devices.

Thermal conductivity: A material’s thermal conductivity is its ability to transfer heat. Thermal conductivity directly influences the material’s temperature increase during its use. In high-power applications, inefficiencies in materials will create heat, thus increasing the temperature of the material—and subsequently changing its electrical characteristics. GaN has a thermal conductivity of 1.3 W/cmK, which is worse than that of silicon’s 1.5 W/cmK.

SiC has a thermal conductivity of 5 W/cmK, making it more than hree times better at transferring thermal loads. This gives SiC an advantage in high-power, high-temperature applications that do not always require high frequency switching but do need higher-voltage operation and improved heat dissipation. Examples include EVs, some solar-power designs, rail traction, wind turbines, grid distribution and industrial and medical imaging.

The main characteristics of GaN and SiC are summarized in Table 1.

Parameter | Symbol | Unit | Si | SiC | GaN | Bandgap | Ec | eV | 1.12 | 3.2 | 3.43 |

|---|---|---|---|---|---|

Relative Dielectric Constant | εs | – | 11.9 | 10 | 9.5 |

Electron Mobility | μn | cm2/(V.s) | 1500 | 700 | 2000 |

Peak Electron Velocity | vpeak | 107> • cm/s | 1 | 2 | 2.5 |

Critical Electric Field | Ec | MV/cm | 0.3 | 3.0 | 3.3 |

Table 1: The main characteristics of SiC and GaN semiconductors

SiC & GaN: Application Examples

WBG components are ideal for power applications, but their use is highly diversified in many sectors. Generally speaking, SiC is commonly used in higher-voltage and higher-power applications, while GaN excels in lower-voltage, higher-frequency and applications where high-efficiency is a primary design goal. Application examples of SiC devices include:

Electric vehicles and quick chargers/contactless power transfer: Replacing a silicon device used in inverters with a low-loss SiC device will enable a highly efficient and lighter weight inverter, extend the EV driving range, and reduce the battery loading. SiC devices with a high withstand voltage and high-frequency operation are optimal for EV quick chargers using contactless power transfer.

Renewable energy inverters (solar and wind): In solar and wind energy systems, at higher power levels, SiC inverters can maximize energy output by minimizing power losses. Another factor that encourages solar manufacturers and engineers to use SiC over other materials is its durability and reliability. Silicon carbide’s reliability enables solar energy systems to achieve the stable longevity they need to operate continuously for over a decade. It is also worth noting that GaN devices are finding a home in smaller solar inverters, especially in the per-panel “micro invertors” where efficiency is highly valued.

Industrial motor drives: SiC provides motor inverters with efficiency improvements, smaller sizes, and better thermal performance, which allows the motor drive to be placed locally or on the motor itself. SiC’s efficiency and high-power handling capabilities improve the performance of industrial motors in factories and industrial plants.

High-voltage power supplies: SiC transistors are instrumental in building efficient and compact high-voltage power supplies.

While SiC dominates the high-power domain, GaN excels at lower power levels (a few kilowatts). GaN transistors offer lower conduction losses and lower switching energy losses, resulting in increased efficiency and a reduced system form factor. Some application examples include:

DC-DC converters (voltage regulators): GaN’s efficiency improvements make it ideal for voltage regulators in various electronic devices.

USB-PD power supplies: These devices must be able to charge quickly and supply multiple voltages to allow connection to various devices. They must also be as compact as possible to allow portability. GaN devices like high electron mobility transistors (HEMTs) are effective in meeting these requirements, since they are high-voltage devices capable of MHz switching while maintaining high efficiency.

Radar systems: The high power density characteristics of GaN devices allow for the design of more compact and lightweight systems, while providing longer detection ranges and higher resolution.

5G and 6G communications towers: GaN’s faster speed and higher power density make it the ideal solution for microwave applications, especially in 5G and 6G networks. The main alternatives, silicon laterally diffused MOS (LDMOS) devices are lower-cost but offer decreased performance. At frequencies of 4 GHz and above, GaN faces little competition.

High-speed wireless communications: GaN-based devices, due to their high breakdown voltage and high electron mobility, can operate in the terahertz frequency range, potentially becoming key enabling technologies for next-generation ultra-high speed

wireless communications.

Optoelectronics: GaN is the core material for blue LEDs and lasers, underpinning display technologies and optical storage, while GaN-based white LEDs are the cornerstone of modern energy-saving solid state lighting solutions.

A qualitative comparison between these two WBG semiconductors is summarized in Table 2.

Feature | SiC | GaN | Voltage | High (above 650 V) | Medium (up to 650 V) |

|---|---|---|

Power | Medium to High | Low to Medium |

Temperature Tolerance | High | Moderate |

Frequency | Moderate | High |

System Size | Larger | Smaller |

Cost | Lower | Higher |

Typical Applications | Power Grids, EV Inverters, Motors | RF Devices, High-Speed Power Supplies, Compact Designs |

Table 2: A qualitative comparison between SiC and GaN

Environmental impact

As industries increasingly prioritize sustainability and environmental responsibility, evaluating the environmental impact of materials like SiC and GaN becomes essential.

SiC boasts several environmental advantages, primarily stemming from its durability and efficiency. Its high conductivity and lower switching losses at high voltages reduce energy losses in power electronics, leading to improved energy efficiency and reduced greenhouse gas emissions. SiC’s robustness and reliability contribute to extended product lifespans, reducing electronic waste.

Furthermore, SiC is considered a relatively abundant material, with ample sources of silicon and carbon available for production, reducing concerns about resource depletion. When it comes to disposal, SiC’s chemical stability makes it inert and non-toxic, posing minimal environmental risks during end-of-life scenarios.

GaN offers environmental benefits primarily through its energy-efficiency and high-performance characteristics. Its low on-resistance and fast switching speeds result in reduced power losses, leading to lower energy consumption and carbon emissions in various applications already discussed above.

Concerns regarding GaN’s environmental impact primarily revolve around the sourcing of gallium, which is a relatively rare element extracted through mining processes. However, ongoing efforts to improve gallium extraction techniques and explore alternative sources aim to mitigate these concerns and ensure sustainable GaN production.

While SiC and GaN offer significant environmental benefits compared to conventional semiconductor materials, ongoing research and development efforts are essential to further optimize their sustainability profiles.

Cost & Supply Chain

One of the primary procurement issues for GaN and SiC is their relatively higher cost vs. silicon. GaN and SiC are more expensive, primarily due to the complexities in their growth and device manufacturing processes. For instance, the epitaxial growth required for high-quality GaN and SiC layers involves advanced techniques that are costlier and less mature than those used for silicon.

Additionally, the availability of large-diameter wafers is limited, raising costs and affecting manufacturing process scalability. This cost barrier can deter some industries, particularly those that operate on thin margins, from adopting these advanced semiconductors.

Supply chain and quality control pose additional challenges. The relatively nascent state of GaN and SiC manufacturing means fewer suppliers can consistently produce high-quality materials. This can lead to bottlenecks and increased lead times.

Moreover, ensuring device reliability and consistancy requires stringent quality control measures.

However, the industry is making substantial strides in addressing these challenges. Advancements in bulk production, epitaxial growth, and device fabrication steadily reduce costs and improve the quality of GaN and SiC devices. Moreover, as economies of scale are achieved, the price disparity with silicon is expected to narrow, resulting in wide bandgap semiconductors achieving even higher adoption.

WBG: The Future of Electronics

The choice between SiC and GaN hinges on an application’s specific requirements. While SiC is the ideal solution for high-voltage, high-power applications, GaN excels in high-frequency, efficiency-driven scenarios. A system designer needs to consider factors like voltage rating, power requirements, frequency range, temperature tolerance, and budget when making a decision. Additionally, if the project demands readily available components and established design practices, SiC might be the more practical choice.

Whichever material is selected, both SiC and GaN represent the future of power electronics. With EVs, renewable energy systems, and next-generation consumer electronics pushing the limits of what’s possible, wide bandgap materials are poised to take center stage.