Spectrum Control has applied its 50 years of experience in managing EMI/EMC to create an expedited approach to building custom connectors for military and aerospace applications. We can now deliver custom filtered connectors to your specifications in only 12 weeks with no NRE.

Filtered Connector Express – Spectrum Control + Richardson RFPD

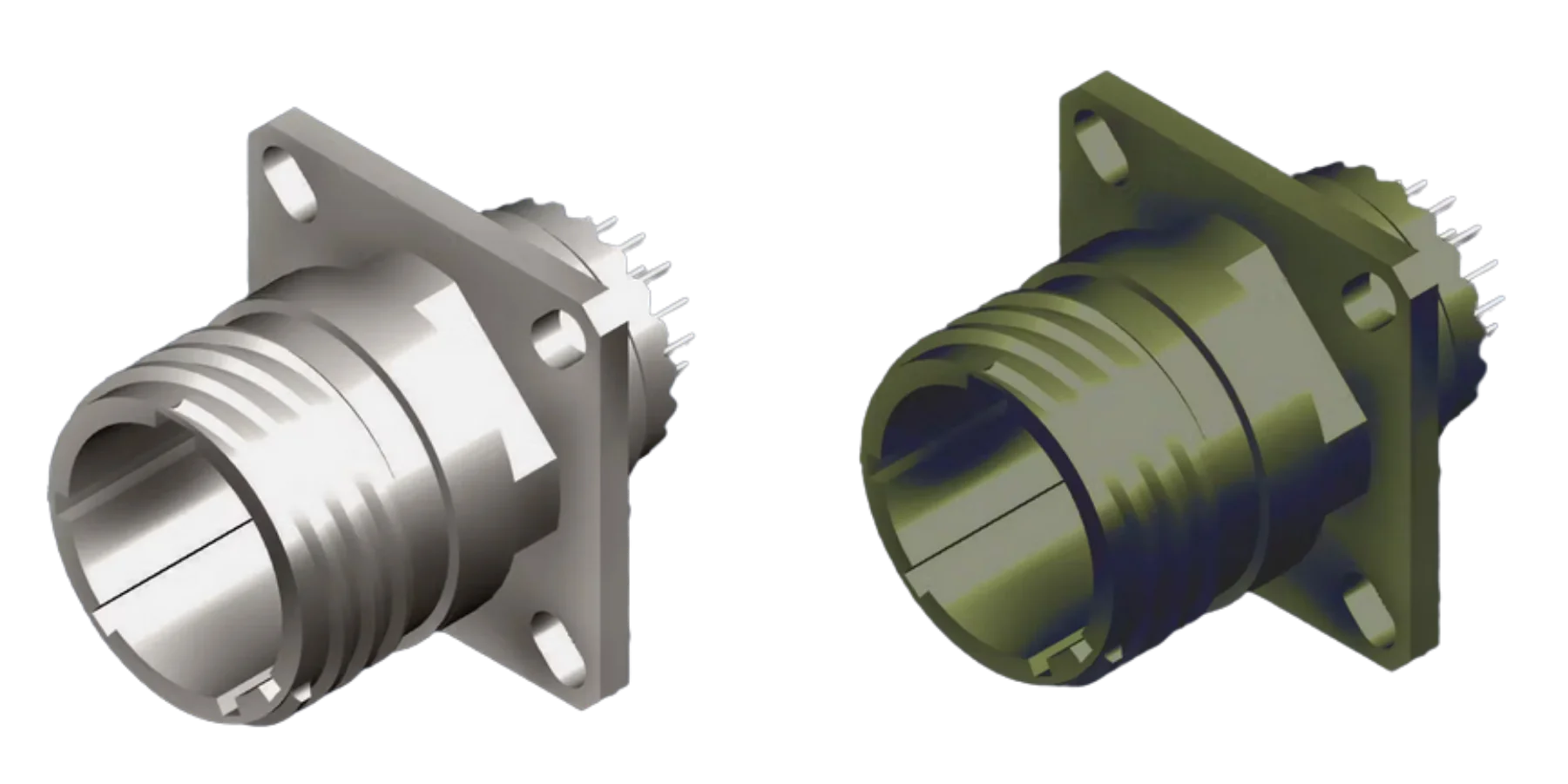

Spectrum Control connectors deliver high performance and flexibility in a single circular package. With prototypes or production units in as little as 12 weeks and zero NRE, speed meets reliability. Advanced EMI filtering, soldered construction, and rugged aluminum shells ensure durability for the toughest environments.

Configure Your Custom Connector

Select your connector, choose a surface finish (Nickel or Olive Drab Cadmium), and pick an insert configuration (13-35, 15-35, or 17-35). Set circuit values for each pin, then submit to discuss pricing or get technical help. Custom options may affect cost and lead time.

Filtered Connector Express – Overview

Spectrum Control delivers connectors engineered for ultimate performance and adaptability. Designed to handle mixed signals in a single circular package, these solutions offer unmatched flexibility.

Key Features

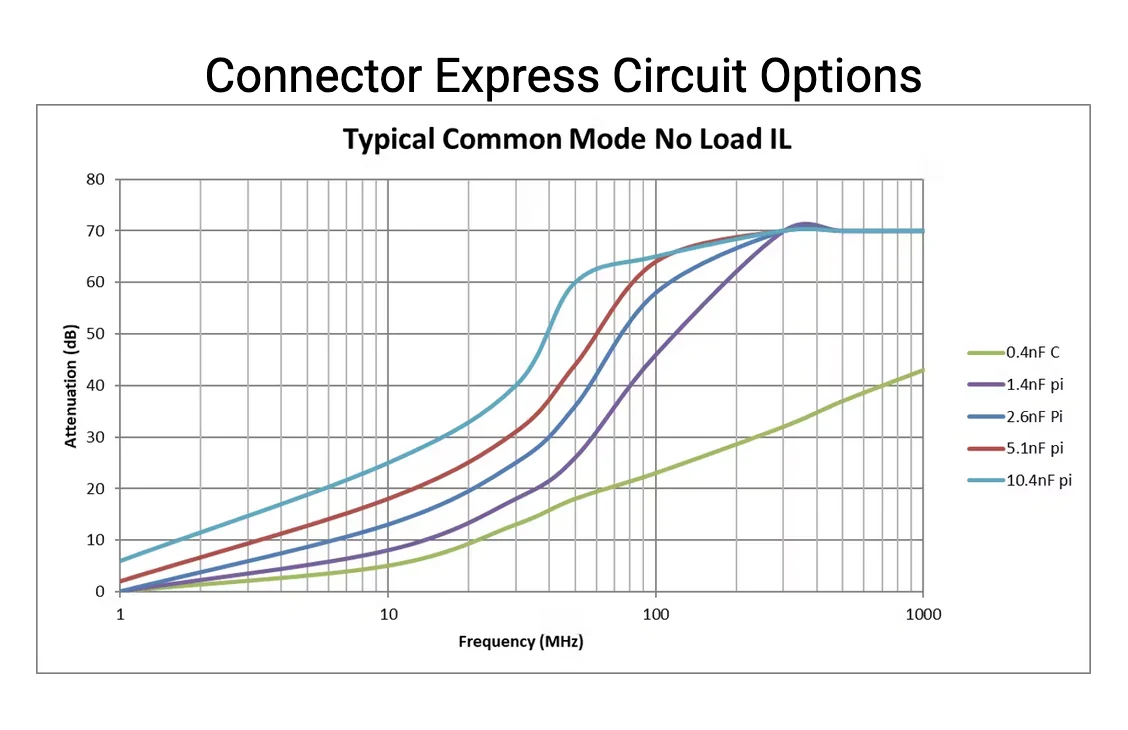

- Configurable connector – with circuits/values for mixed signals in a single circular connector package

- Quick turnaround – for quick prototyping or production units, from specs to finished products in 12 weeks; no NRE

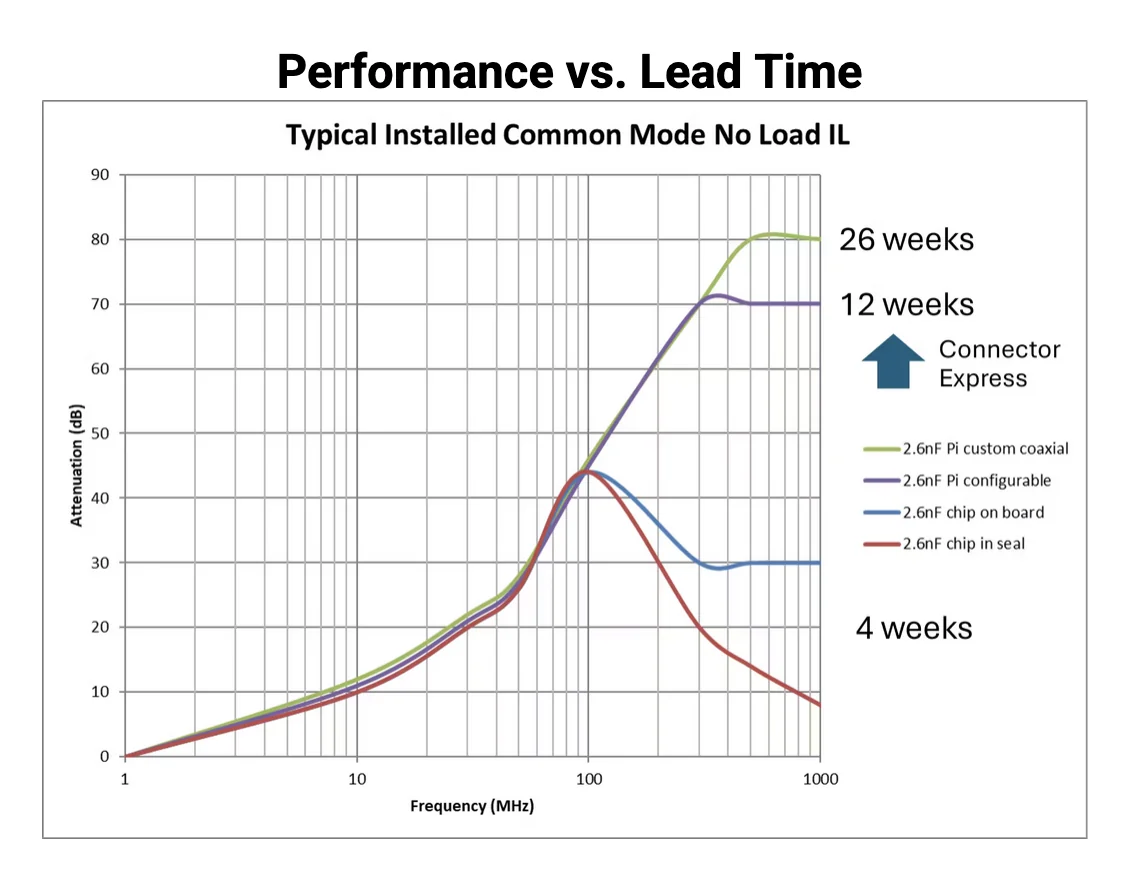

- Superior EMI filtering – combination of a planar and substrate filtering for superior performance versus chip-on-board (COB) or chip-in-seal versions

- Soldered construction – for better high-frequency performance over mechanical designs

- Large capacitance pin-to pin-ratio range – for consistent performance with power and signal filtering in a single package

- Aluminum shell – for rugged environmental and/or weight sensitive applications

Download STP files

Select from two surface finishes:

- Nickel

- ODCAD

- 3 Pin Configurations: 13-35, 15-35, 17-35

Standard Product Attributes

MIL-DTL-38999 Series III | Square flange (wall mount) |

Aluminum shell | PC tail termination |

N keying | DWV: 200 VDC working/500 VDC |

Male contact gender | Current rating: 5 Amps |

Size 22D contact size | |

Quality Assurance

All EMI filtered connectors undergo extensive testing to ensure that all products meet specification requirements. Many tests are performed 100% by computer-controlled test sets, including capacitance, dissipation factor, dielectric withstanding voltage, and Insulation resistance as routine. Others are tested on a sample basis as applicable. Test plans can be configured to specific customer requirements.

Qualification/special testing – Spectrum has a fully qualified test laboratory and can provide additional acceptance testing upon the customer’s request. This could be a one-time qualification exercise or ongoing periodic testing.

Test Specifications

- All test conditions at 25±5°C & 30-50% relative humidity

- DF at 1.0 Vrms @ 1 KHz ±1%

- IL per MIL-STD-220, no load condition

- IR per MIL-STD-202, Method 302

- DWV per MIL-STD-202, Method 302, 1-5 sec. 50 mA max.

- CAP. per MIL-STD-202, Method 305, 1.0 VRMS @ 1KHz. ±1%

Additional Resources – from Spectrum Control

White Paper

Mitigating Electromagnetic Interference with Filtered Connectors

Designed by engineers for engineers! Here is the technical data behind this novel approach to filtered connectors.

FEATURED RESOURCE

Spectrum Control High-Power SAW Filters

As the only US-based manufacturer of high power SAW filters, Spectrum Control uses an advanced manufacturing process that delivers higher power, tighter bandwidths, and expanded package options.