The MACOM KV CAPS™ Si capacitors feature very low loss and excellent stability by virtue of their novel internal construction and very high quality dielectric layers. These capacitors are available as unpackaged chips. The chips have gold bonding surfaces on both terminals to enable excellent bonding and minimum contact resistance.

A Novel Construction: MACOM KV Capacitors

MACOM KV CAPS™ silicon capacitors are high-density, high-working voltage silicon capacitors which employ a novel topology that essentially folds the parallel plates of the capacitors into three-dimensional structures, producing greater capacitance per unit area of die footprint than that of a simple parallel plate capacitor. This technology employs high reliability materials and wafer processing, which have been staples of the semiconductor industry for decades.

Higher surface area means high density, which results in more capacitance for a given size.

MACOM’s KV CAPS™ have the highest available working voltage ratings for silicon-based capacitors. The 50 VDC working voltage KV capacitors are ideal for use in demanding chip-and-wire circuits for DC blocking, AC bypass, and resonant-circuit applications.

What was the key to the innovation of KV CAPS™?

MACOM KV CAPS™ utilize trenches in the top surface of the silicon die. The silicon substrate has very low resistivity and is utilized as the bottom plate of the structure. Thin film dielectric material is deposited on the entire top surface of the substrate to form the middle, insulating layer of the capacitor. The top surface of the dielectric layer is coated with a conductive material to form the top plate of the capacitor structure. This geometry effectively increases the common area of the parallel plates since the areas of the bottoms, tops and side walls of the trenches all comprise the effective area of the parallel plate capacitor structure.

The 50V, 200V and 500V families of capacitors are available as unpackaged chips, optimized for chip-and-wire hybrid circuit applications. The outermost layers of the topside and backside contacts are gold.

50 V MACOM KV CAPS™: Si Hi-Q Capacitors

The novel construction of MACOM KV™ offers many performance advantages. These devices are fundamentally parallel-plate capacitors formed on a highly conductive silicon substrate.

Part Number | Capacitance Value (pF) | Capacitance Tolerance (%) | Working Volt DC WVDC (V) | Chip Dimensions (mm) | |

|---|---|---|---|---|---|

| MKVC-050100-14530G | 47 | 10 | 50 | 0.35 x 0.35 x 0.254 |

| MKVC-0547R0-14530G | 100 | 10 | 50 | 0.35 x 0.35 x 0.254 |

Features & Benefits

- High capacitance per footprint area while supporting large working voltages.

- Excellent long-term capacitance stability

- High quality factor

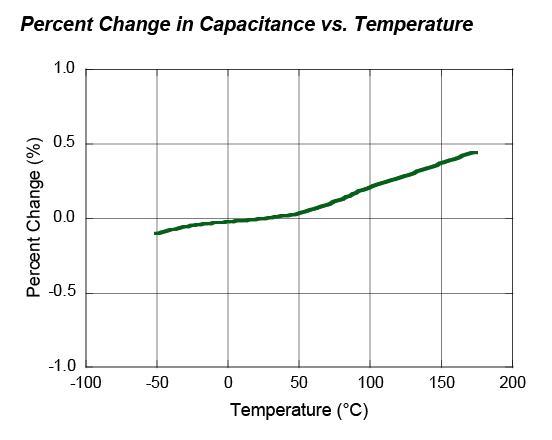

- Very small change in capacitance versus temperature.

- Non-magnetic materials/construction

- Compatible with industry-standard chip-and-wire construction.

- Metallized back-side die contact.

- Topside metal is suitable for wire/ ribbon bonding.

High Stability Over Temperature

50 V MACOM KV CAPS™: Application Information

Recommended Die Attach Methods

Unpackaged die may be attached to a circuit medium using solder or conductive epoxy.

Land Pad Design

When designing a pad for conductive epoxy attach it is recommended that the size of the pad be 0.004 inches (0.100 mm) larger than the die on all sides to allow for proper filleting. For 80/20 AuSn eutectic solder attach a thicker gold plating is recommended for proper intermetallic formation. Typical range is 50 – 100 microinches. When designing the land please refer to the datasheet for the recommended land pad.

Solder Die Attach

Solder die attach may be accomplished using a eutectic solder, such as Au(80)/Sn(20), leaded solders such as Sn63Pb37 or with any of several RoHS-compatible solders such as Sn96.53Ag0.5Cu (SAC305) etc. For leaded or RoHS solder pastes it is recommended that a no clean solder paste be used to prevent trapped fluxes which cannot be cleaned as recommended by IPC-7093.

Conductive Epoxy Die Attach

Solder die attach may be accomplished using a eutectic solder, such as Au(80)/Sn(20), leaded solders such as Sn63Pb37 or with any of several RoHS-compatible solders such as Sn96.53Ag0.5Cu (SAC305) etc. For leaded or RoHS solder pastes it is recommended that a no clean solder paste be used to prevent trapped fluxes which cannot be cleaned as recommended by IPC-7093.

Au(80)/Sn(20) Eutectic Solder Attach

80/20 AuSn solder is commonly supplied as a preform. The recommended preform size is 0.005 inches (0.125 mm) undersized from each edge. Typical preform thickness are 0.001 inches (0.025 mm). MACOM recommends the solder temperature profile shown below for Au(80)/Sn(20) eutectic solder die attach. The solder is typically flowed using heat and forming gas. It is important that the following maximum conditions must not be exceeded during die attach: > maximum solder temperature: 350°C > maximum peak temperature duration: 5 s

Wire/Ribbon Bonding

While the construction of MACOM’s KV™ is very robust, it is recommended that wires or ribbons should be attached near to the center of the top contact to prevent mechanical damage, such as micro cracking, to the die which could degrade the working voltage capability of the die. Thermo-compression or ultrasonic bonding can be used. For most capacitance values, the top contact of the KV™ capacitor is sufficiently large to accept the attachment of multiple wires or ribbons. The top contact of the capacitor has a gold plating. Prior to wire or ribbon bonding, plasma cleaning may be required to remove any organic contaminants that could affect the quality of the bond interface. The parameters used can vary, depending on the wire bonding process and wire/ribbon type used. Common alloys which can be used include CuPdAu and Au wires.