Silicon Carbide JFETs from onsemi

SiC JFET

- Normally-on SiC JFET

- Lowest available RDS on

- VGS in on-state directly proportional to

Tj → ideal self-monitoring power device - 1700 V, RDS(on) … 400 mΩ

- 1200 V, RDS(on) … 7.1 mΩ – 70 mΩ

- 750 V, RDS(on) … 4.3 mΩ – 4.8 mΩ

- Target application: Circuit Breakers,

Current limiting applications

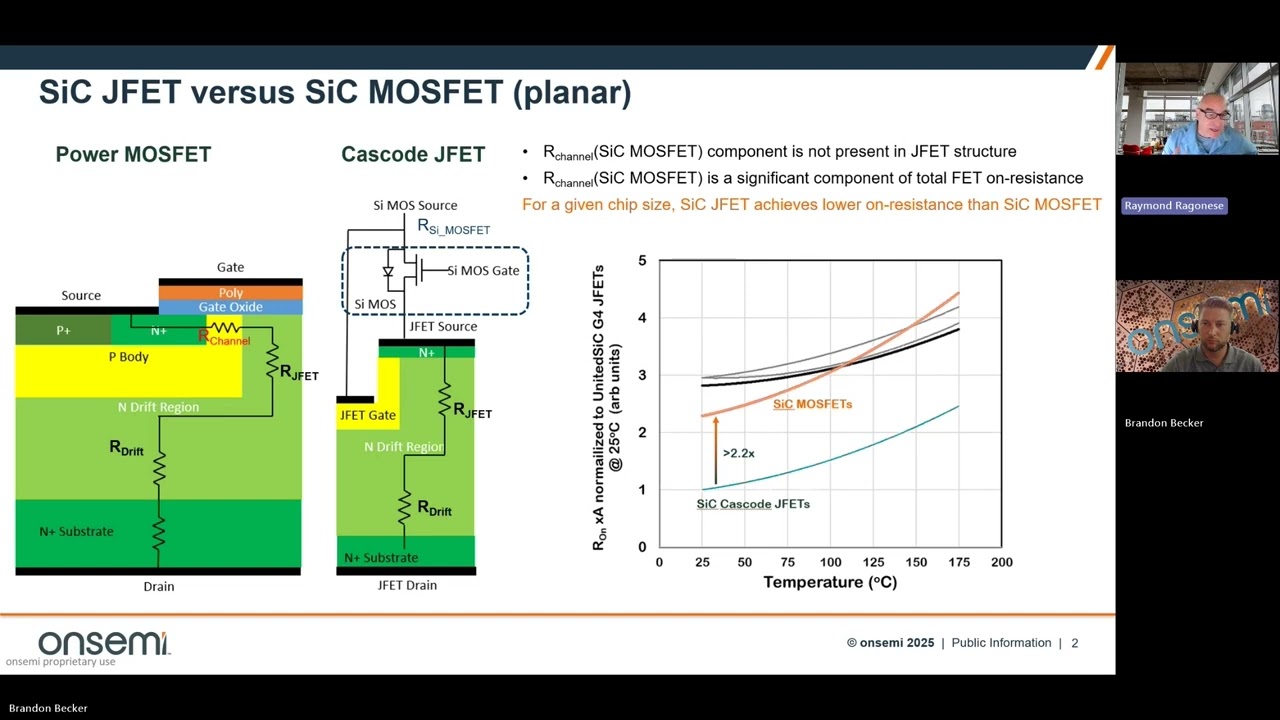

SiC Cascode JFET

- 2 chips in co-packed Cascode

- Pick and place replacement for

standard normally-off MOSFET - Ultra low RDS on, high pulse current is

- 1700 V, RDS(on) … 410 mΩ

- 1200 V, RDS(on) … 9 mΩ – 410 mΩ

- 650 V, RDS(on) … 7 mΩ – 85 mΩ

- Target application: Power Supply,

Inverters, Chargers, DC-DC Converters

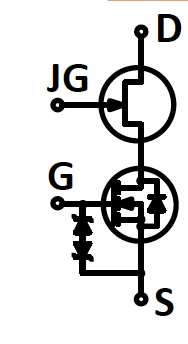

SiC Combo JFET

- 2 chips in 1 package → Combo JFET

- Separate access to MOSFET and JFET

gates → better switching dV/dt control - Ultra low RDS(on), high pulse current

- 1200 V, RDS(on) ≤ 10 mΩ

- 750 V, RDS(on) … 5 mΩ – 10 mΩ

- Target application: Solid state circuit

breaker, disconnect switches

SiC JFETs

onsemi offers SiC JFETs, SiC Cascode JFETs and SiC Combo JFETs, each type has its unique characteristics and is suitable to different applications. SiC JFET allows the SSCB to operate at up to 175°C, which is the material limit for an enclosure; SiC is able to withstand even higher temperatures.

Gen4 – 750 V | Gen4 – 750 V | Gen4 – 750 V | ||||

|---|---|---|---|---|---|---|

TO-247 (4L) |  TOLL | Top Cool–TOLT |  TO-247 (4L) | Top Cool–TSOP |  D2PAK (7L) | |

JFET | UJ4N075005K4S 4 mΩ | UJ4N075004L8S 4 mΩ | NTBT004N075J4 4 mΩ | UF3N120007K4S 7 mΩ | UF3N170400B7S 400 mΩ | |

Combo-JFET | UG4SC075006K4S 5 mΩ | UG4SC075005L8S 5 mΩ | NTBT005N075SCBJ4 5 mΩ | |||

Combo-JFET | UG4SC075009K4S 9 mΩ | UG4SC120009K4SH 9 mΩ | ||||

Combo-JFET | UG4SC075011K4S 11 mΩ | |||||

- Product In Development

Why chose SiC JFET or Combo JFET

Coolest operation

- Lowest Power Loss

- JFET Option: Normally ON or normally OFF

Smallest space

- Minimal Part Count: Heat budget and paralleling

- Stacked Chips: two chips in a single package, “Combo JFET”

- Combined functions: On-chip temperature sensing

- Combined functions: JFET or Combo JFET as current sensor

Dependable

- Voltage rating: 750V provide the necessary safety margin

- Rugged: dependable switching

- Simple construction

Easy-To-Use

- Simple drive method

Essential Guide for Engineers Developing Next-Gen Power Systems

Explore onsemi’s latest System Solutions Guide for Solid State Circuit Breaker (SSCB) applications, supported by Richardson RFPD. Discover key products like onsemi’s SiC JFETs, offering superior performance over super junction MOSFETs. Tap into onsemi’s broad semiconductor portfolio and technical expertise for industrial, automotive, and energy infrastructure designs.

Why Solid-State Circuit Breakers? (SSCBs)

Free from the limitations of magnetic coils, semiconductor switches operate hundreds of times faster than electromechanical relays, interrupting current before it becomes hazardous. Without mechanical parts, semiconductor switches can perform unlimited connect/disconnect cycles without degradation. This innovative approach replaces traditional moving parts with semiconductors and advanced software algorithms, enabling faster interruption of extreme currents. Solid-state technology ensures extremely fast fault interruption, clearing faults in microseconds compared to milliseconds for mechanical circuit breakers of the same size. Wide bandgap (WBG) semiconductors offer superior material properties, allowing power devices to operate at higher voltages, temperatures, and switching rates.

Electro-Mechanical | Solid-State | |

|---|---|---|

Design | Contains moving parts and contacts | Uses Semiconductor as a switch |

Speed | Milliseconds | Microseconds |

Durability | Mechanical wear and tear | Durable |

Precision | Limits are set by manufacturer | Offer precise control |

Arcing | Yes | No |

Power Dissipation | Lower efficiency | Higher efficiency |

Power Dissipation | Yes | No |

Solid-State Circuit Breakers v. Traditional Electromechanical Circuit Breakers

There’s been a recent trend to replace traditional electromechanical circuit breakers with solid-state circuit breakers to protect expensive power electronics equipment. What are the differences between traditional and solid-state breakers? What system level benefits are gained converting to solid-state? What design resources are available to support engineers developing their own solid-state circuit breakers? These questions and more are answered in Richardson RFPD’s Tech Chat with onsemi on solid-state circuit breakers vs. traditional electromechanical circuit breakers.

Playlist

7:38