Semiconductor device fabrication processes have several distinct and intricate steps. Power supplies used in semiconductor fab equipment are essential for every task at the front and back end of the process. Due to its power density, reliability, and design flexibility, engineers are seeing the benefits of using Silicon Carbide (SiC) compared with silicon-based power supplies in applications where it hasn’t been used before.

Power density and flexibility are why Wolfspeed and Astrodyne TDI (ATDI) joined forces to exploit the benefits of SiC technology to meet the diverse power supply needs of modern semiconductor fab/process equipment. Our combined efforts have enabled higher power density through the adoption of SiC devices, most notably with ATDI’s new Kodiak power supply platform, which achieves a power density of 40 W/in3. Specifically, Wolfspeed’s long history in developing robust SiC-based solutions is helping ATDI provide better power converters, which in turn help customers improve process control.

Related Content

Wolfspeed Top-Side Cooled SiC MOSFET

Top-side cooled power semiconductors are gaining interest across the power electronics design community. Improved thermal…

Power Modules: One Shortcut to EMI Compliance

Electronic devices that are in proximity or share common conductors are susceptible to electromagnetic interference (EMI)…

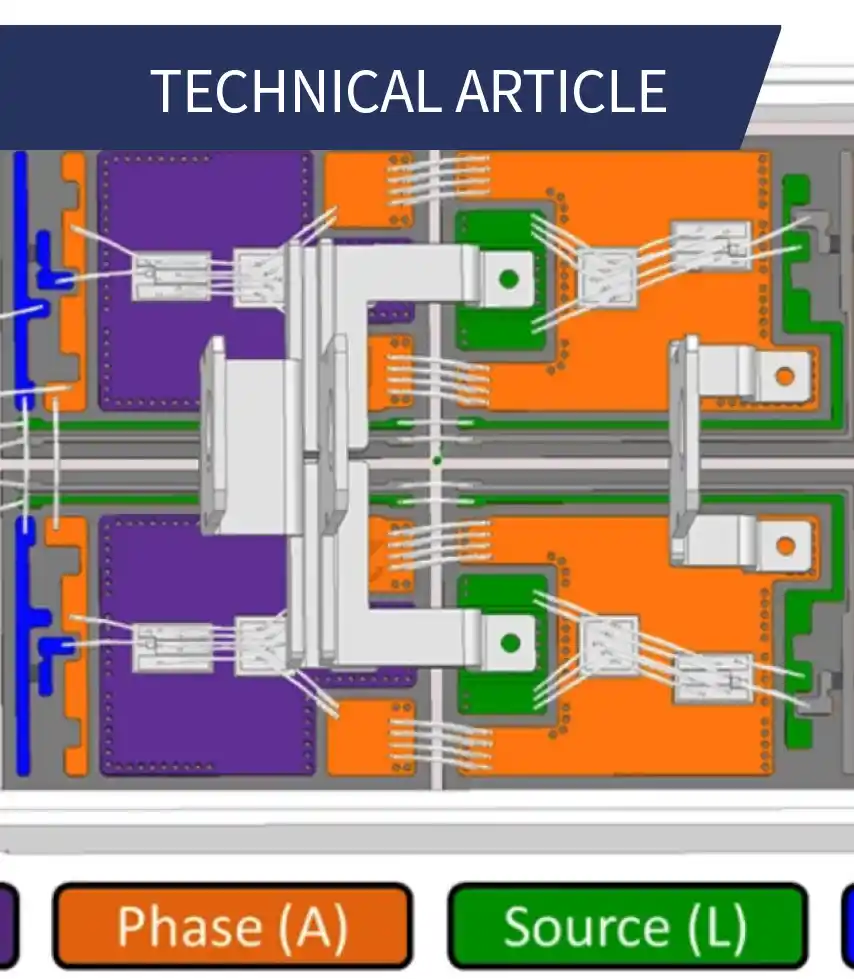

Benefits of Designing with Wolfspeed Silicon Carbide in Low Voltage Motor Drives

Silicon carbide is enabling a global shift to embedded industrial low voltage motor drives where the drive and motor are combined into one unit, resulting in…